The Costs of Dropping Objects

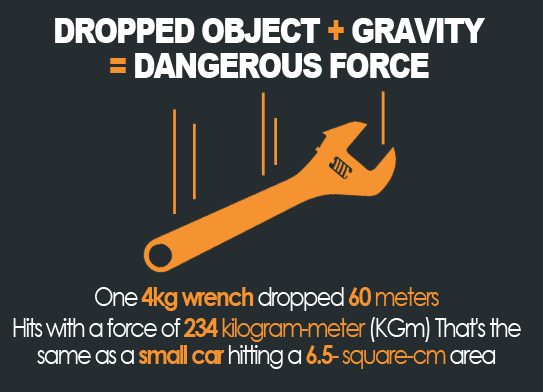

The costs of dropped objects are injury/fatality, damage, and lost productivity. According to certain reports from the US Bureau of Labor Statistics, there were 255 deaths and almost 48,000 injuries because of falling objects in 2016.

The costs of dropped objects are injury/fatality, damage, and lost productivity. According to certain reports from the US Bureau of Labor Statistics, there were 255 deaths and almost 48,000 injuries because of falling objects in 2016.

The two types of damage are the ones caused by the object itself and something that the dropped object hits. Damage can also be caused to the tool or equipment due to the fall. Environmental damage can also occur if the object is not reclaimed or results in hazardous conditions such as radiation leakage.

Lost productivity can refer to financial loss when work has to be stopped, or it can also be the time lost by a worker to retrieve the tool or a new piece of equipment. More time can be consumed when the damage is done versus the time needed for supervising and monitoring the area before the damage happens. The time spent repairing things after the loss occurs could have been used in monitoring and checking the equipment and area to make sure all items are in order.

Safety Measures

Dropped objects are an inherent hazard in a working environment, but safety and prevention measures must be done to avoid danger. There are safety measures and prevention for dropped objects.

Personal Protective Equipment

PPE, which means Personal Protective Equipment, protects the user against safety and health risks at work. Examples are safety goggles, visors gloves, industrial safety helmets, harnesses, and high visibility clothing. The amount of equipment needed depends on how risky the work is. PPE must be in good condition and not defective when it is being used and has different categories, namely: respiratory protection, eye protection, hand protection, hearing protection, head protection, and skin protection.

Masks are used for respiratory protection; goggles can be used for eye protection, gloves with cuffs and sleeves, earplugs or earmuffs for ear protection, helmets for head protection and sunburn cream for skin protection.

Administrative Controls

Administrative controls look to train workers and make them more aware of risk management when implementing procedures. Signs, stickers and barricade tape can help workers identify if an area is safe or not. The use of toolboxes and training workers can assist in risk management. Checklists are also useful in determining what steps are done or not yet done.

The area around the workplace should be maintained and regularly checked to avoid slipping and sliding. Supervising and regular monitoring is a must. It is also essential to check if nothing is left behind and everything is tidy for the next workers using the workplace to not be inconvenienced.

A Final Word About Dropped Object Safety

Be sure to sue a connection point on all tools and use specific adaptation devices for tools which do not already have a connection point. Tether tools and equipment and secure it to an anchor point either attached to you physically or to a portion of a stable structure to prevent the object from accidentally falling. Making sure any container is closed tightly to prevent it from spilling if it gets knocked over.

The costs of dropped objects are injury/fatality, damage, and lost productivity. According to certain reports from the US Bureau of Labor Statistics, there were 255 deaths and almost 48,000 injuries because of falling objects in 2016.

The costs of dropped objects are injury/fatality, damage, and lost productivity. According to certain reports from the US Bureau of Labor Statistics, there were 255 deaths and almost 48,000 injuries because of falling objects in 2016.